Common Pitfalls in CE Testing and How to Avoid Them

In the complex world of CE testing, manufacturers face a myriad of challenges to ensure compliance with European Union regulations. At Green Mountain Electromagnetics, we understand the importance of navigating these hurdles. This article highlights the most common pitfalls in CE testing and provides practical solutions to help you avoid costly mistakes.

Inadequate Documentation

Thorough technical documentation is the foundation of successful CE marking. Many manufacturers underestimate the importance of maintaining comprehensive records, including test results, risk management files and conformity assessment procedures. Failing to provide complete documentation can lead to delays or even rejection by notified bodies and competent authorities.

To avoid documentation pitfalls, manufacturers should:

-

Establish a structured documentation system that aligns with the requirements of relevant directives and standards.

-

Ensure accurate recording and easy accessibility of all test data, performance criteria, and safety evaluations.

-

Regularly review and update your documentation to reflect any changes in your products or the regulatory landscape.

Overlooking Pre-Compliance Testing

Skipping pre-compliance testing is a common mistake that can have significant consequences down the line. Pre-compliance testing allows manufacturers to identify potential issues early in the development process, saving time and resources in the long run.

To make the most of pre-compliance testing:

-

Conduct thorough risk analysis to determine the scope of testing required for the specific device.

-

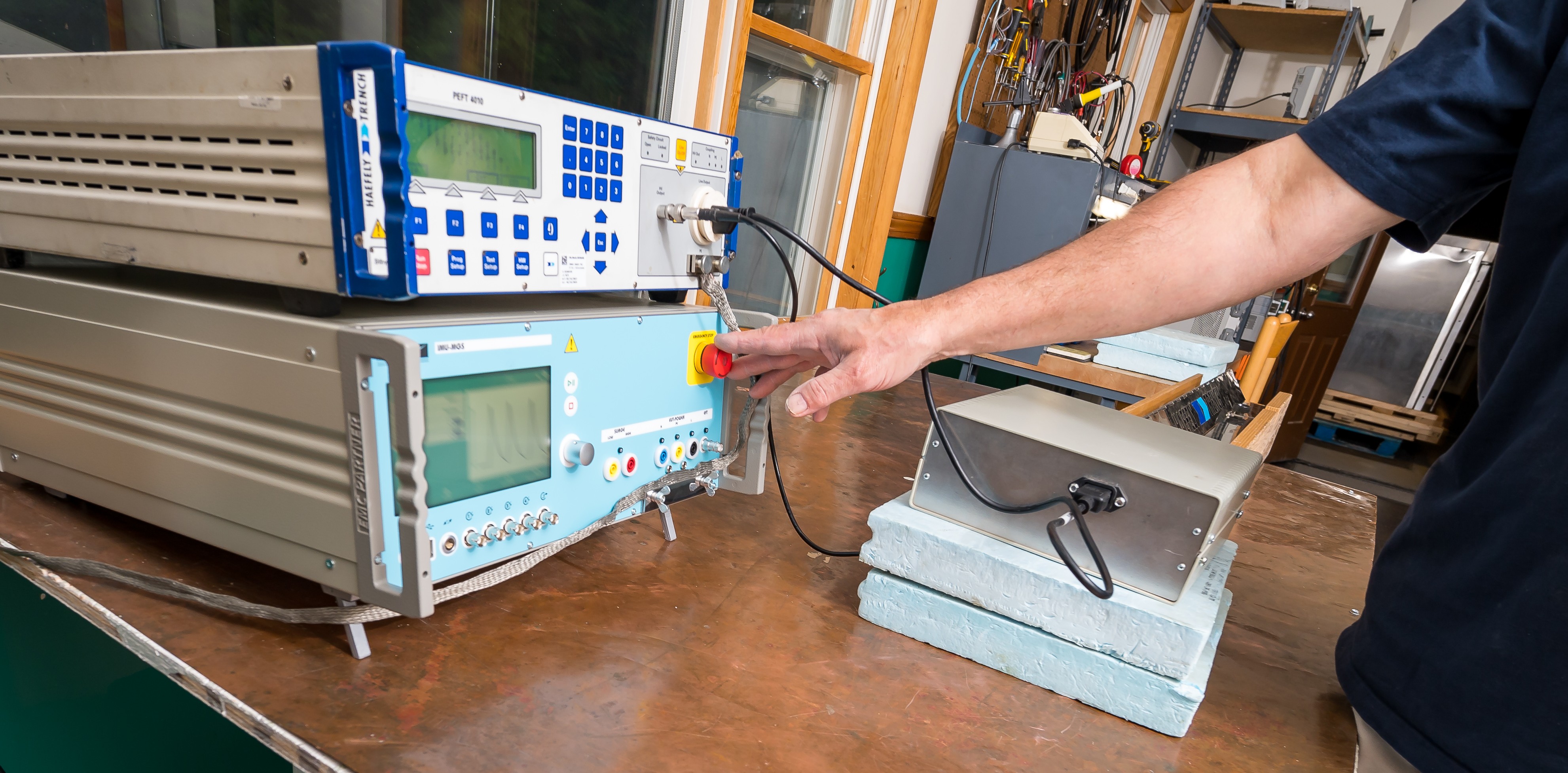

Utilize a partner with a reliable testing laboratory to assess the product's compliance.

-

Address any identified issues before proceeding to formal compliance testing to minimize the risk of failure.

Misinterpreting CE Marking Requirements

CE marking requirements can be complex, and misinterpretation is a common pitfall. Manufacturers must have a clear understanding of the applicable directives, harmonized standards, and transitional provisions relevant to their products.

To ensure accurate interpretation:

-

Be familiar with the specific requirements for the product category.

-

Seek guidance from notified bodies, competent authorities or experienced compliance partners like Green Mountain Electromagnetics.

-

Stay up-to-date with legislative changes and guidance documents to ensure ongoing compliance.

Insufficient Testing of Product Variants

Failing to adequately test product variants is another common pitfall. Manufacturers must ensure that all versions of their devices fully comply with the relevant requirements. This includes testing different configurations, materials, or software versions.

To achieve comprehensive variant testing:

Identify all relevant product variants and determine the necessary testing scope for each.

Develop a systematic testing plan that covers all variants and ensures consistent data collection and reporting.

Consider using automated testing tools and solutions to streamline the process and reduce the risk of human error.

Overlooking Risk Assessments

Risk assessments are a cornerstone of CE marking. However, they are often overlooked or inadequately conducted, leading to potential safety hazards and non-compliance.

To avoid risk assessment pitfalls, manufacturers should:

Conduct comprehensive risk assessments that consider all possible hazards associated with their products.

Involve experts in the risk assessment process to identify potential risks that may be overlooked.

Maintain detailed records of all risk assessments and review them regularly to ensure ongoing compliance.

Ignoring Product Changes

Any changes or modifications to a product after initial testing can affect its compliance status. Many manufacturers fail to re-evaluate their products following modifications which can impact its compliance with CE marking requirements.

To avoid this pitfall, manufacturers should:

Treat compliance as an ongoing process rather than a one-time event, recognizing that product changes may necessitate re-testing.

Re-test products whenever significant changes are made to ensure they still meet the necessary requirements.

Implement robust version control practices to effectively track and manage product changes over time.

Ensure CE Compliance With Green Mountain Electromagnetics

Navigating the CE testing process requires precision, partnership and a proactive approach to avoiding common pitfalls. Green Mountain Electromagnetics is committed to being a trusted partner in this journey. Our expertise, efficiency, and personalized service can guide manufacturers through the CE testing process, helping avoid costly mistakes and achieve compliance with confidence.

Contact us today to learn more about how we can support your CE testing needs.