Preventing EMC Failures: What Engineers Need to Know About Shielding, Layout and Enclosures

Every year, thousands of products face costly delays because they fail electromagnetic compatibility (EMC) tests late in development. Yet, many of these issues could be avoided entirely by integrating EMC design strategies from day one.

Delayed certifications can cost companies thousands in lost revenue, missed launches and redesign expenses. Industry labs report that between 40% and 60% of products fail initial EMC testing, often due to preventable design flaws such as emissions, grounding faults or shielding weaknesses.

By prioritizing electromagnetic compatibility (EMC) from the first schematic, manufacturers save time, control costs and improve overall product reliability. A proactive design mindset replaces the costly cycle of "design, test and fix" with "designing for compliance" from the start.

Fundamentals of EMC Shielding: Principles and Materials

Shielding acts as a product's first defense against unwanted electromagnetic interference. Without proper material selection and grounding, even a strong design can fail compliance testing, forcing expensive and time-consuming redesigns.

Effective shielding requires attention to conductivity, continuity and frequency behavior. Metals like copper, aluminum and nickel are preferred for their high conductivity. Consistent, continuous shielding prevents leakage; small gaps or poor joints are often the hidden cause of elevated emissions. At higher frequencies, tighter seams and specialized coatings become critical.

Selecting the right shielding materials early in development, guided by standards such as EN 61326-1, reduces rework risk and improves first-pass certification rates.

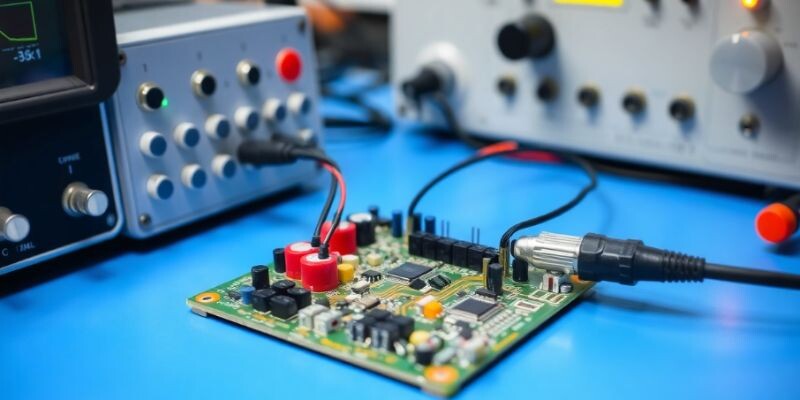

PCB Layout Best Practices for Minimizing EMI

PCB layout decisions have a profound effect on a product's electromagnetic behavior. Poorly designed boards can act as radiators, emitting noise that undermines compliance.

A continuous ground plane minimizes loop areas and creates stable return paths, reducing the potential for unwanted radiation. High-speed signals should follow short, direct routes with careful impedance control. Separating analog and digital sections helps avoid internal coupling. Well-placed decoupling capacitors near power pins filter transient noise effectively.

Incorporating these practices early aligns designs with IPC standards such as IPC-2221B. As highlighted in discussions around early EMC testing strategies, good layout fundamentals consistently lead to stronger compliance outcomes.

Enclosure Design Strategies for Effective Shielding

An enclosure isn't just a housing — it's an active part of the product's EMC defense. Ignoring enclosure design during development often results in non-compliance surprises during testing.

Metallic or metallized cases provide superior EMI containment compared to plastic enclosures. Conductive gaskets help maintain shield continuity across seams and access points. Shielded connectors and careful cable management prevent emissions from escaping through interconnects.

Strong collaboration between mechanical and electrical engineering teams at the design stage ensures the enclosure supports system-level compliance goals. Practical insights into how enclosure decisions impact final testing can help teams prioritize the right features early.

Common EMC Design Pitfalls and How to Avoid Them

Certain design oversights repeatedly cause problems during EMC testing. Addressing them proactively avoids costly delays.

Floating shields that aren’t properly bonded provide little real-world benefit and often lead to elevated emissions. Densely populated PCBs encourage unintended coupling, especially when mixed-signal layouts are not carefully managed. Relying too heavily on ferrites to "fix" emissions problems often masks deeper systemic issues.

Teams that emphasize proper grounding, thoughtful component placement, and strong signal integrity from the outset consistently achieve better compliance outcomes. Awareness of these common pitfalls in CE testing equips teams to design more predictably successful products.

Testing Early and Iteratively: Catching Issues Before Certification

Waiting until final certification testing to validate EMC performance introduces significant risk. Early-stage pre-compliance testing helps teams identify vulnerabilities while changes are still affordable and practical.

Screening for radiated emissions during prototype stages pinpoints problem areas before production tooling locks designs in place. Verifying shielding effectiveness and operational resilience against conducted and radiated disturbances builds confidence long before formal testing begins.

Resources like the IEC 61000-4 series outline structured approaches to testing immunity and emissions. Adopting pre-compliance as part of a regular development workflow enables teams to meet tough market timelines without last-minute surprises, especially in highly integrated or complex product designs.

Partnering with an EMC Lab for Proactive Compliance Support

Navigating the evolving landscape of EMC standards and regulatory expectations requires both technical expertise and strategic foresight. An experienced EMC lab partner provides critical design feedback, accelerates validation processes, and helps minimize costly testing failures.

Early collaboration enables vulnerability detection during schematic and layout stages. Pre-compliance evaluations confirm design direction before full formal submissions. Skilled labs also assist in navigating key directives, such as EN 55032 for multimedia equipment and FCC Part 15 for U.S. market compliance.

At Green Mountain Electromagnetics, proactive engagement has helped clients cut time-to-market by months and in some cases years, ensuring smoother certifications and stronger product launches. Manufacturers depend on GME’s industry leading turnaround times and professional guidance to enter the marketplace as swiftly as possible.

Designing for EMC Success from the Beginning

Building EMC compliance into your product development process isn't just prudent engineering — it's a strategic advantage. Products that meet regulatory standards the first time avoid costly rework, protect development schedules and strengthen brand reputations.

By embedding smart shielding choices, sound PCB layouts and robust enclosure strategies early in development, teams create stronger, more competitive products. Small design decisions made today can eliminate major certification barriers down the road.

Ready to engineer EMC success into your next project? Schedule a design consultation with our team today.