Pre-Compliance CE Testing: How to Catch Problems Before the Final Test

Waiting until the final stages of product development to conduct CE compliance testing can feel like saving your parachute check for right before the jump. The truth is, by then, your options are limited—and expensive. That's where pre-compliance CE testing comes in. This strategic step allows companies to identify and resolve potential issues early in the process, saving time, reducing costs and increasing confidence in your product's ability to pass the final certification.

For manufacturers developing products for European markets, understanding and implementing pre-compliance testing is not just smart—it's essential. It provides critical insights and helps ensure that your device is on track to meet EMC and safety requirements before you commit to the full, formal CE certification process.

Why Pre-Compliance Testing Is a Strategic Advantage

-

Reduces risk of failure during final testing

-

Supports faster time to market by identifying issues early

-

Improves product quality and reliability from the ground up

What Is Pre-Compliance CE Testing?

Pre-compliance testing serves as your product's dress rehearsal before the main certification event.

Unlike formal CE testing, this preparatory step:

-

Simulates official testing standards in a flexible environment

-

Allows you to evaluate EMC and safety performance early

-

Provides actionable data without the high stakes of formal certification

-

Identifies potential compliance issues while design changes are still feasible

The core advantage? Flexibility. Since testing occurs earlier in development, your team maintains the agility to make necessary adjustments without derailing production schedules or budgets.

Pre-compliance doesn't result in an official CE mark—instead, it gives you something even more valuable: confidence that your product is on track for successful certification when it matters most.

The High Costs of Skipping Pre-Compliance

Skipping pre-compliance testing often seems like a time-saving decision, but it's typically a false economy. Products that fail final CE testing face not only the cost of retesting but also significant project delays and additional engineering cycles. For businesses on tight timelines or operating in competitive markets, these delays can compromise profitability and reputation.

Moreover, a failed certification test often exposes design flaws that are more difficult—and more expensive—to resolve late in the process. The earlier these issues are caught, the more manageable they are to fix, both technically and financially.

Ideal Timing: When to Begin Pre-Compliance Testing

The ideal window: When your product reaches the final prototype stage but before mass production begins.

At this critical juncture, you have:

-

Most functional features implemented and working

-

A design that closely resembles the final product

-

Enough flexibility to make necessary adjustments

-

Time to address issues without delaying market entry

Testing during this phase transforms the certification process from a pass/fail event into a strategic advantage. You're not just checking boxes—you're gathering intelligence that drives smarter design decisions throughout development.

Common Tests Conducted in Pre-Compliance

While the exact testing needs will vary by product, certain assessments frequently reveal potential problems early:

Radiated and Conducted Emissions: These tests determine whether your product is emitting unwanted electromagnetic energy that could interfere with other devices. Non-compliance here is a frequent cause of failure in final CE testing.

Electrostatic Discharge (ESD): Verifies how well your product handles electrostatic shocks, such as those from human contact or nearby electronics—common in everyday use environments.

Electrical Fast Transients (EFT) and Surge Immunity: Assesses resilience against power line disturbances, which are especially critical for equipment connected to public or industrial grids.

Radiated Immunity: Tests how your device performs in environments with surrounding electromagnetic fields, ensuring it remains functional under real-world conditions.

Don't Risk Your Product Timeline

Is your product ready for CE certification? Green Mountain Electromagnetic can identify potential compliance issues before they become costly problems.

Request a Pre-Compliance Testing Quote

-

Detailed assessment of your specific product requirements

-

Customized testing plan tailored to your device category

-

Clear pricing and timeline expectations

-

Expert guidance through the entire process

Beyond Compliance: Product and Process Improvements

Pre-compliance testing isn't only about passing CE certification—it's also about building better products. By identifying weaknesses early, development teams can proactively improve design robustness, reduce field failures and deliver more reliable products to market.

This process also facilitates better internal collaboration. Engineering, quality assurance and regulatory teams benefit from shared data and earlier alignment, which can streamline the development timeline and reduce miscommunication.

Selecting the Right Testing Partner

Choosing a lab with deep expertise and a collaborative approach makes all the difference. At Green Mountain Electromagnetics, we work with you to interpret results and guide improvements, not just run tests and deliver reports. With over three decades of experience in EMC and product safety, we understand the technical challenges and the business pressures our clients face.

Our Vermont-based facility combines precision testing with personalized support. Whether you're new to CE compliance or refining an established process, we offer a partnership that prioritizes speed, clarity, and cost-effectiveness.

How to Integrate Pre-Compliance into Your Workflow

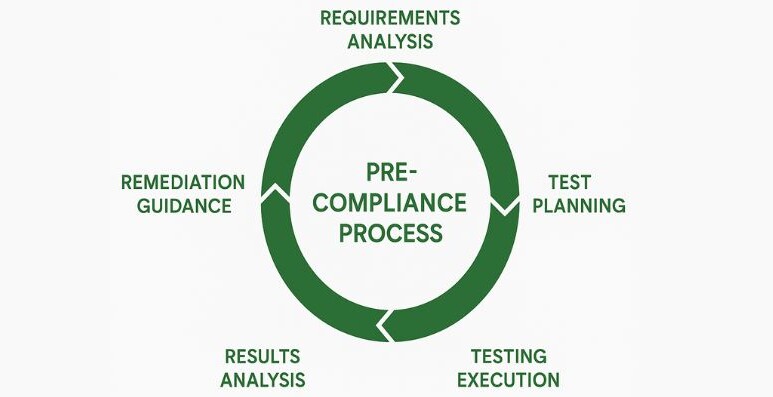

Incorporating pre-compliance testing into your development cycle is a matter of planning and prioritization. Start by identifying compliance requirements early in your design process. Engage a qualified testing lab—like GME—early to consult on potential risk areas based on your product type and market.

Next, build testing into your project schedule. Treat it as a checkpoint, not a detour. Use the data to inform design decisions and reduce uncertainty. This approach ensures that your final CE certification process goes smoothly and predictably, avoiding last-minute surprises.

Don't Leave Compliance to Chance

Pre-compliance CE testing isn't just another checkbox—it's your insurance against costly delays, failed certifications and compromised market opportunities.

At Green Mountain Electromagnetics, we've helped hundreds of manufacturers navigate the certification process with confidence. Our pre-compliance approach helps companies identify issues early when they're less expensive to fix while significantly increasing first-time certification pass rates.

We’ll work with you to understand your specific product requirements and develop a testing plan that addresses your unique compliance challenges.