How EMC Testing Saves CE Projects from Costly Delays, Failures and Missed Deadlines

You can design the most advanced product in your market — but if EMC testing issues surface late in the CE process, your entire launch timeline can quickly go off track.

At Green Mountain Electromagnetics (GME), we regularly help manufacturers recover stalled or failing CE projects. From rushed documentation to EMI failures at the worst possible time, we’ve seen firsthand how easily deadlines can slip — and how the right test lab partner can help prevent it.

As the father-son duo at GME like to say: "EMI is always ruining deadlines."

Here’s how EMC testing can make the difference between a missed shipment and a market-ready product.

Where CE Projects Commonly Get Stuck

Even experienced engineering teams face roadblocks in the CE process. Based on recent projects, here are the most common points of failure:

-

No budget or management sign-off for compliance: Testing often gets left out of planning conversations until it's too late.

-

Timing disconnects: Sales or product teams may advertise a CE-marked product that hasn’t been tested yet.

-

Component quality gaps: Mixing highly rated parts with unverified or substandard components can lead to failures, often due to overlooked EMC design flaws.

-

Engineering tunnel vision: Teams focus on solving electrical or mechanical issues without stepping back to consider system-level compliance.

-

Documentation gaps: Weak or missing labels, markings, or declarations slow down the CE submission process.

-

Confusion between EMC and product safety rules: Grounding and signal return requirements can vary, and misapplying best practices leads to test failures.

These issues can derail even a well-intentioned CE strategy — especially if you’re not working with a test lab that proactively identifies and helps resolve them.

CE Marking Isn't Just Paperwork — It's Proof of Performance

One of the most common misconceptions is that CE marking is simply a self-certification or label you apply after assembly.

In reality, CE marking is a legal declaration that the product meets all applicable EU directives related to safety, EMC, environmental impact, and more. For most electronic and electrical products, that includes:

Per the European Commission, CE marking is the manufacturer’s way of demonstrating "conformity with health, safety, and environmental protection standards for products sold within the European Economic Area (EEA)."

Most products do not require a Notified Body (third-party certifier). Instead, they require proper EMC testing, documentation, and a Declaration of Conformity (DoC).

EMC Testing is the Most Likely Point of Failure

At GME, we often see companies attempt to complete EMC testing in the final days of a launch cycle — only to fail emissions or immunity tests and face weeks of redesign.

Unlike mechanical or visual inspection steps, EMC compliance requires:

-

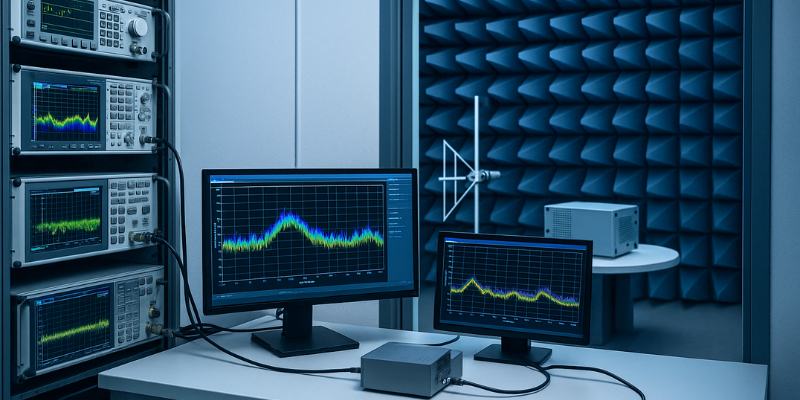

Lab-based testing using calibrated antennas and test chambers

-

Precise setup per harmonized EN standards

-

Interpretation of test failures and real-time troubleshooting

That’s why working with an ISO/IEC 17025 accredited lab like GME is critical. Accreditation means your test results are recognized throughout the EU and accepted by regulatory authorities without dispute.

Worried about failing EMC late in your project?

Share your block diagram or prototype with us and we’ll flag the top EMC risks before you freeze your design.

Reactive vs Proactive EMC: The Real Difference

Here’s the pattern we see over and over:

|

Aspect |

Reactive (Late EMC) |

Proactive (Early EMC) |

|

When testing happens |

After design is frozen |

During design & prototype phases |

|

Impact of failures |

Costly respins, missed deadlines |

Minor tweaks, manageable schedule impact |

|

Lab relationship |

Pass/fail gatekeeper |

Design & schedule partner |

|

Schedule predictability |

Low |

High |

|

Total cost of compliance |

Higher (rework, rush, delay costs) |

Lower (fewer surprises, smoother testing) |

Case Snapshot: Turning Around a CE Timeline Under Pressure

A recent client — an industrial controls manufacturer — came to GME with an urgent CE deadline. Their first round of EMC testing had failed, and they lacked the internal resources to course-correct quickly.

GME stepped in to:

-

Help interpret which directives and harmonized standards applied

-

Review their marking and documentation for legal completeness

-

Provide engineering guidance on safety-critical components

-

Identify and resolve both conducted and radiated immunity failures

Thanks to this support, the client met their deadline and is now working with GME to CE-mark their entire product line. Their success wasn’t about passing a test — it was about having a partner who could help them recover a critical milestone.

Final Tip: Start EMC Testing Early, Not After You Hit a Wall

If you're in the planning phase for CE marking, here’s the simplest way to stay on schedule:

-

Engage with a test lab before you freeze your design.

-

Confirm which directives and standards apply.

-

Ask for guidance on common failure points.

Whether you're building wireless devices, lab instruments, or industrial systems, EMC testing isn't just a checkbox. It's the make-or-break step in CE success.

Common Questions We Hear from CE Project Leads

Most electronic and electrical products have EMC requirements, either under the EMC Directive or another directive that has EMC built in. There are edge cases, but if it has electronics and goes into the EU, you should assume EMC has to be addressed.

Pre-certified modules help, but they don’t guarantee your complete system will meet EMC requirements. Your PCB, enclosure, cabling, and everything around that module matter just as much.

You get data — emissions plots, immunity failures, operating conditions. The next step is turning that into a short, prioritized list of fixes and a plan for re-testing. That’s where collaboration with the lab really pays off.

For a complex product, expect several days in the lab for a full campaign, plus whatever time you need for fixes and any re-tests. During busy seasons, lab booking lead times can add more weeks. This is why early conversations help.

An ISO/IEC 17025–accredited lab gives you confidence that the people, equipment, and methods are recognized by regulators and notified bodies. It makes your reports more defensible and your CE file stronger.

Need to Move Fast on a CE Project?

Schedule a 30-minute EMC pre-compliance review with GME.